Not everyone immediately thinks of the industrial and automotive sectors when they think of silicone. However, silicone is widely used as a material in the automotive sector and will continue to establish itself as electromobility continues to progress, as it has very positive properties as a sealing and insulation material. Silicone is also becoming increasingly important in industrial applications.

The reasons for this are silicone’s favourable product properties such as temperature and UV resistance.

Examples of products are 1C silicone seals, multi-component components, 2C silicone injection moulding, lenses made of high-purity translucent liquid silicones, sensors embedded in LSR, etc. The list of possible applications can be continued almost indefinitely.

Successful customer projects

Our LSR and HTV moulds and cold runner systems open up diverse and increasingly new areas of application in industry and turn the products into reality. Sealing applications, valve diaphragms, optical lenses and shock absorbers are just a small spectrum of what is needed in today’s industrial sectors. Constant research and development drive the application possibilities of silicone into ever new spheres. The Sky is the Limit!

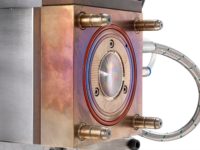

Seals

Radial and axial seals as standard parts or in customized designs are implemented quickly and cost-effectively using our standardized mould concepts. We also offer the right solution in combination with inserts, whether plastic or metal.

Diaphragms and valves

The reliable conveyance of liquids and gases often places increased demands: Food compatibility, stable recovery behaviour and biocompatibility are properties that can often only be met with LSR or HTV silicones.

Multi-component parts

Silicone-metal connections as well as thermoplastic-LSR multi-component parts are achieved in the classic 2C process or with inserts.

The designs of the machine solutions, the concepts for thermal separation within the mould system and the material pairings to be produced are essential in this area. Achieving the right interplay all of the factors is a challenge that has to be met.

Lens technology

The special, translucent and extremely low-viscosity LSR materials require the highest degree of geometric precision and surface quality in the production of the moulds.

We were involved in the development of LSR lenses for LED headlights from the very beginning and led them to series production. Today this is established and state of the art!